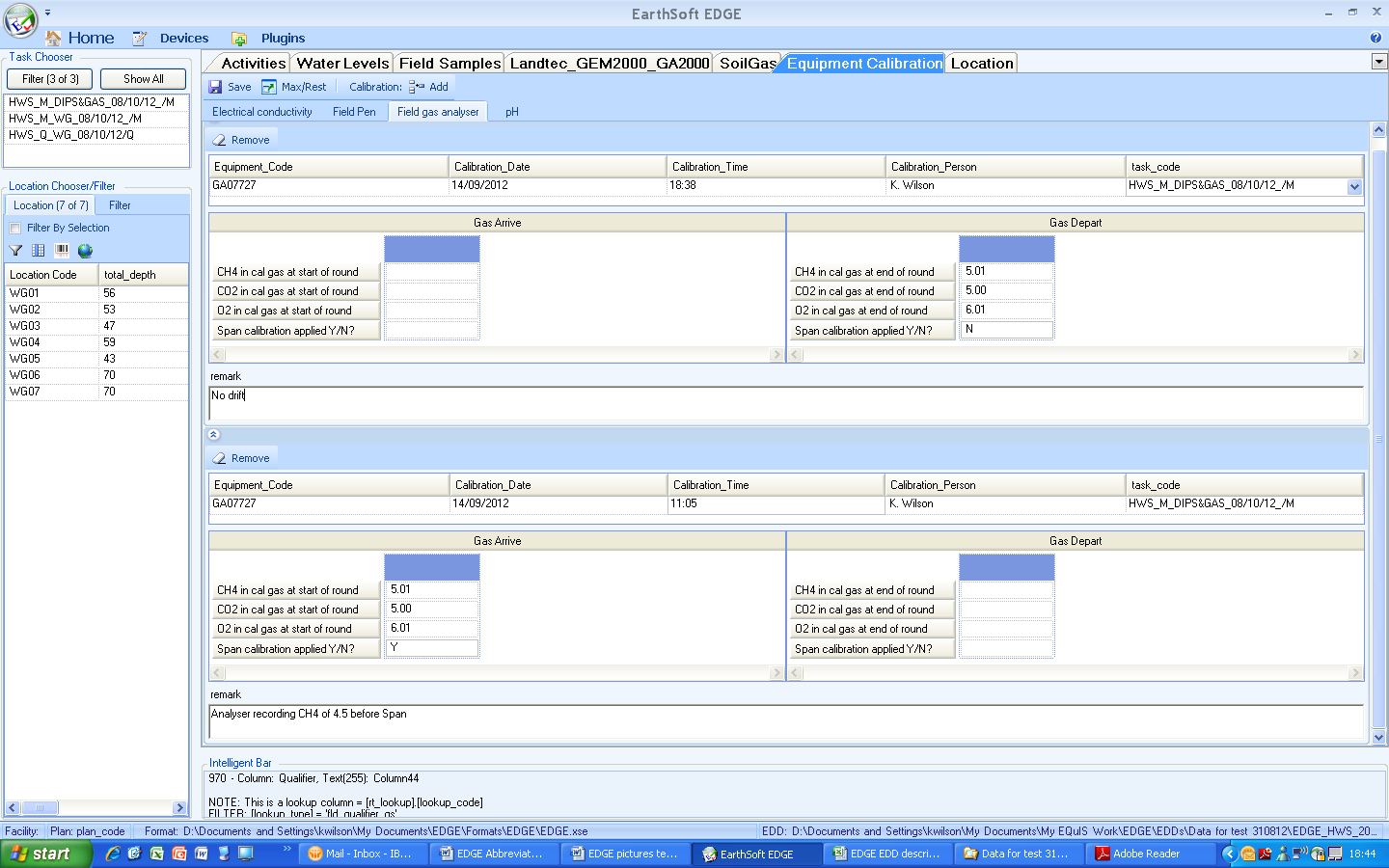

The geotechnical Instruments analysers are required to be checked and/or calibrated at the start and end of each site visit. As a result there will be two calibration panes for the analysers at different times in each Field EDD containing gas monitoring requirements.

The two pane names include ‘5-5-6’. This represents the calibration gas concentration, in this case 5.00 CH4, 5.01% CO2, 6.02% oxygen. If a gas with a different set of concentrations is planned to be used please speak to CEMEX in advance of the gas being used.

It is not necessary to complete a gas Span on each occasion, just to run the calibration gas through the instrument to determine whether it is reading in range. Only if the readings are off is a Span required and only on a start of visit calibration check. A Span would not be required or expected at the end of the visit. The purpose of this check is to record whether there has been any drift in the instrument during the monitoring round.

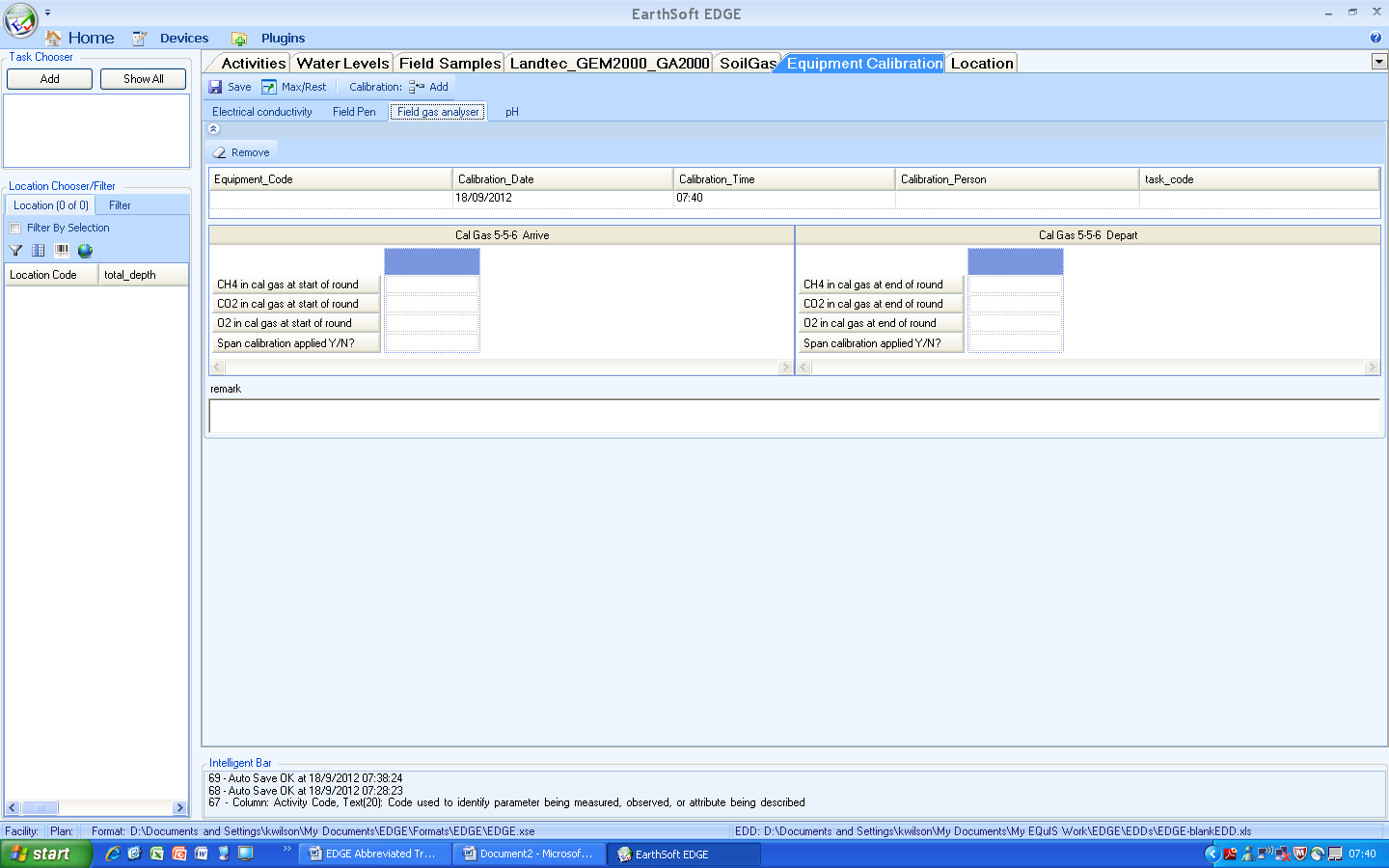

To create a record:

1)Select the Equipment Calibration tab

2)Select the Field Gas Analyser tab

3)Select the Add icon to create a new form.

4)To create a form for a visit at the start of the round

a.Select the Equipment Code from the drop down list

b.The date and time are set for the time the record was created so open the record when the task is in hand

c.Select your name from the drop down list

d.Enter the Task Code for the first task in the Task Chooser list that includes Gas in its name

e.Use the left pane of the form, Cal Gas 5-5-6 – Arrive to record the gas check/calibration when arriving on site

f.After switching on the analyser, connect the calibration gas to the analyser inlet, turn on the analyser pump and open the cal gas valve. Allow the readings to stabilise and then record the stable gas readings for CH4, CO2 and O2 in the respective fields. If only a calibration check is made and the readings are acceptable, enter N against the Span Calibration Applied Y/N field. If the readings are unacceptable and a Span is carried out enter a Y against the Span Calibration Applied Y/N field and enter the gas readings observed after the Span is completed.

g.As this is a start of visit check/Span the right had pane, Cal Gas 5-5-6 – Depart should be left entirely blank

5)At the end of the monitoring round, a new form should be created by repeating steps 1 to 3 above

a.Repeat steps 4a to 4c above, and a new form will be added to the top of the page,

b.Enter the Task Code used in the Cal Gas 5-5-6 – Arrive pane

c.After switching on the analyser, connect the calibration gas to the analyser inlet, turn on the analyser pump and open the cal gas valve. Allow the readings to stabilise and then record the stable gas readings for CH4, CO2 and O2 in the respective fields in the Cal Gas 5-5-6 – Depart pane. Leave the Arrive pane blank.

d.As this is a gas calibration check, Span correction should not be made and the Span Calibration Applied Y/N field should be entered as N